During elaboration or use of a material or a new product, surfaces often play a major role. Wear, corrosion, adhesion… arise from the physical and chemical properties of the surfaces and interfaces. So, they need to be characterised in order to well understand the interactions occurring.

In many fields, surface analysis techniques help to control and improve material performances, thus leading to an increase in competitiveness :

- In Research and Development, surface analysis techniques are a knowledge tool, and help during process optimisation.

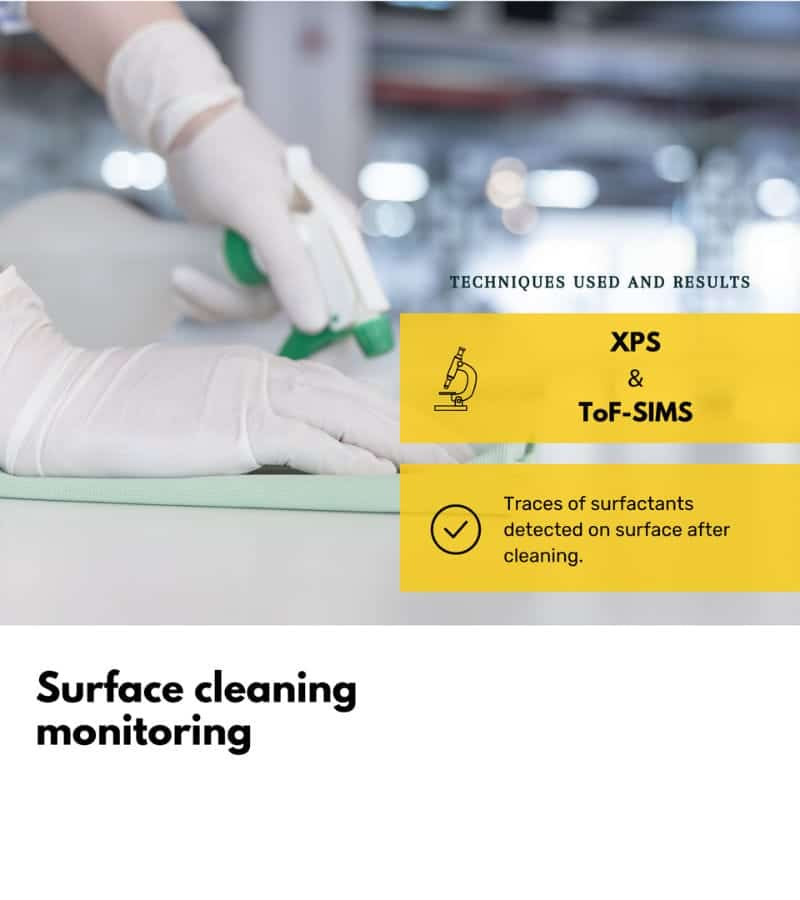

- In Production, surface analysis techniques can become a real tool to check quality and reproductibility of surface states.

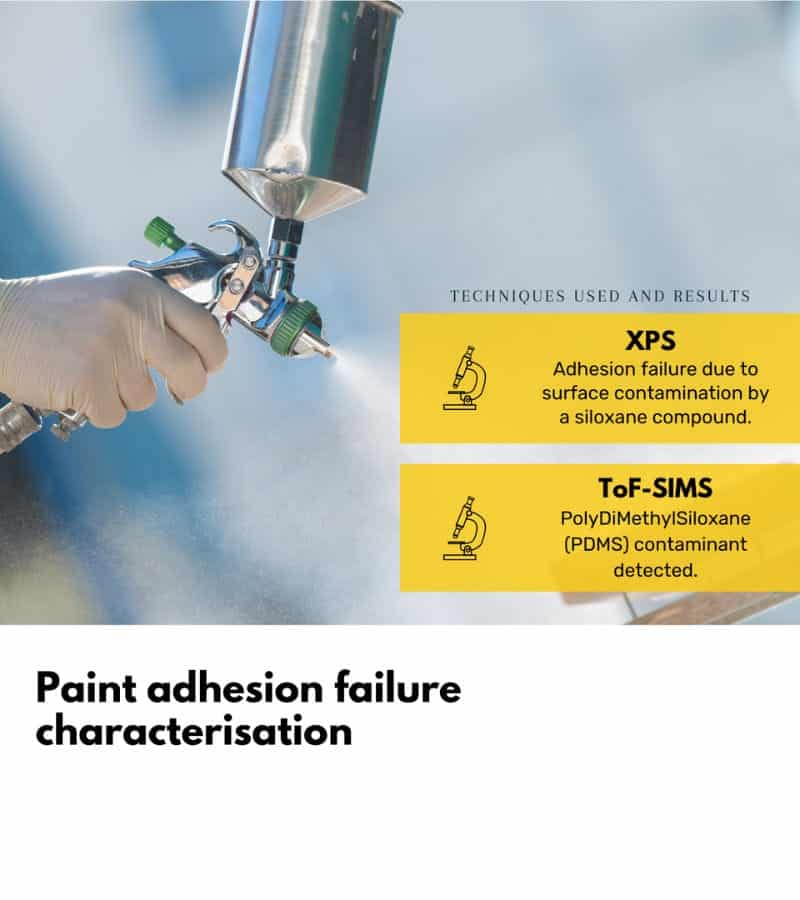

- For Problem solving (weldability, adhesion, contamination…), surface analysis techniques are also powerful means of investigation.

Industrial case studies

As experts in surface analysis, SERMA Technologies’ surface analysis laboratory is involved in a wide range of industrial cases to control and improve the quality of material performance.

We carry out a wide range of analyses to meet our customers’ requirements.

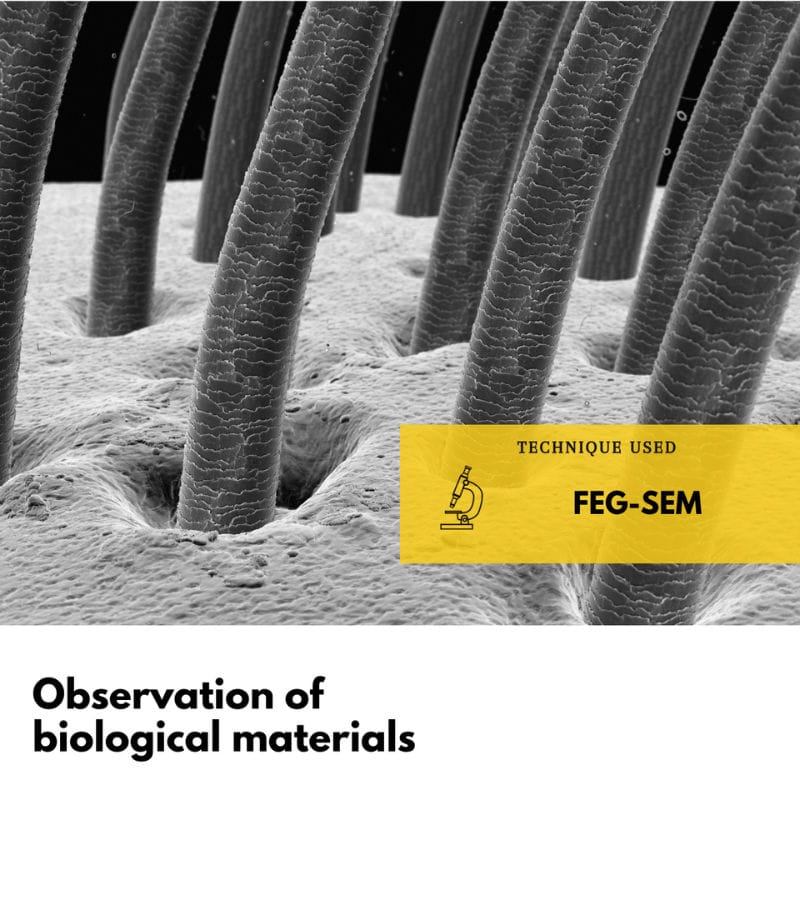

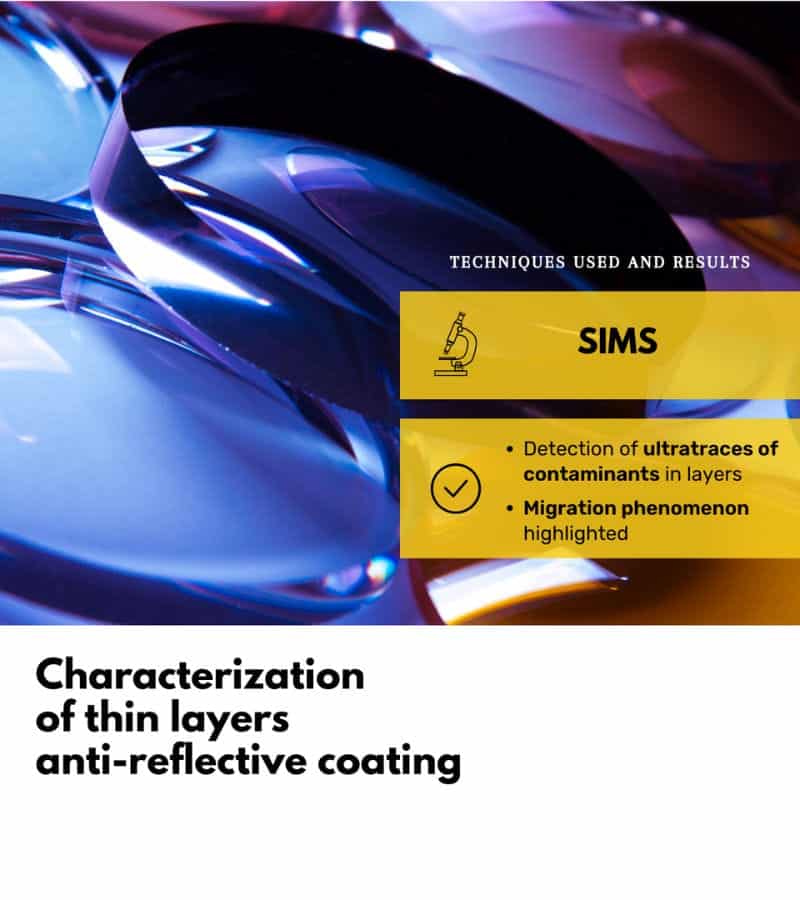

Surface cleaning monitoring, paint adhesion failure characterisation, observation of insect, characterization of thin films with anti-reflective coatings: we adapt to your requirements!