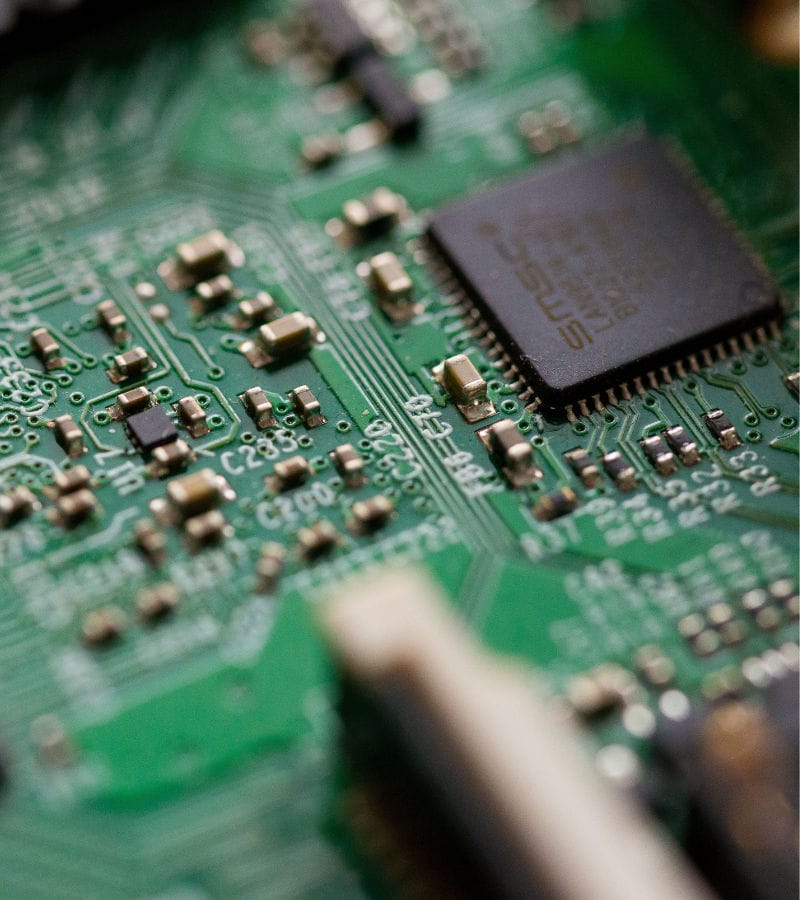

SERMA Technologies works with manufacturers and users of electronic components and conducts static, dynamic and functional measurements on all types of electronic components: passive, discrete, analogue, digital, mixed, ASIC, RF/Microwave, etc.

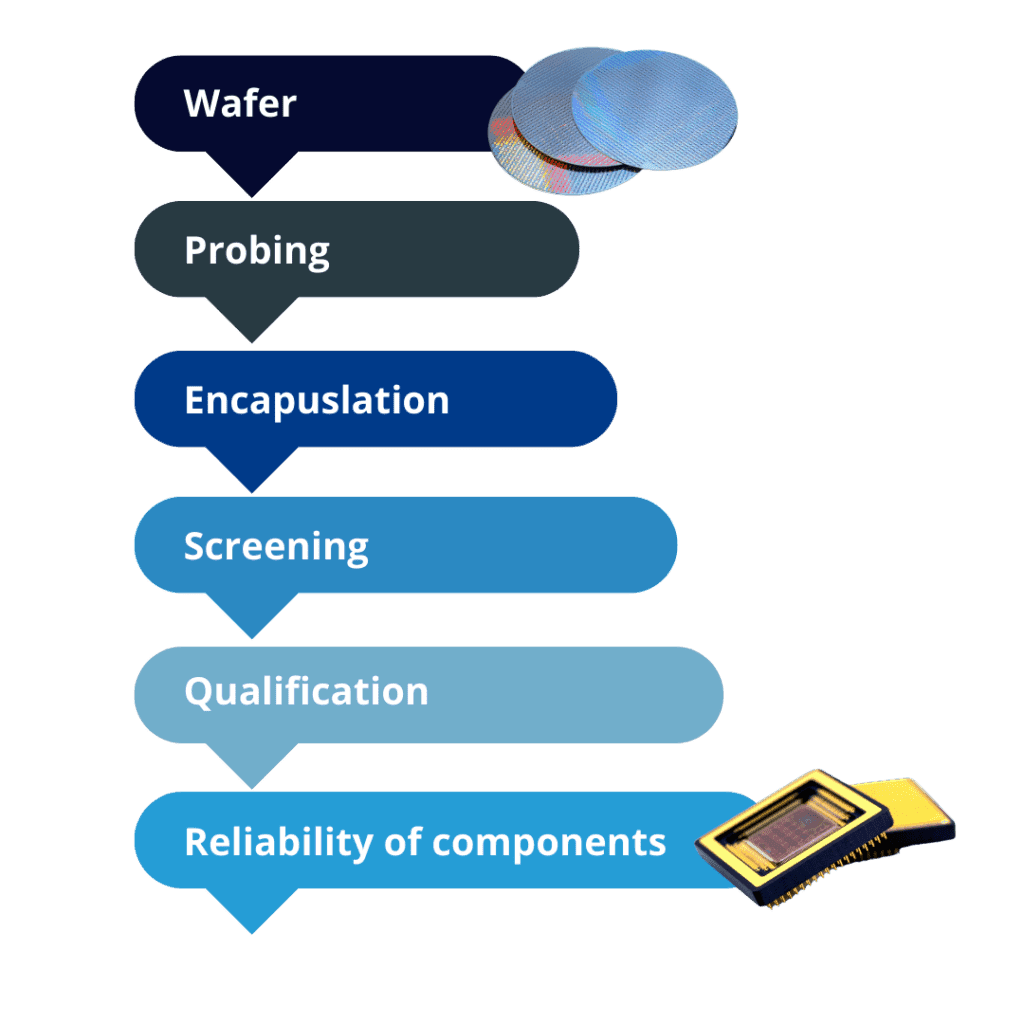

These tests enable us to characterise and assess the component, ensure its reliability and qualify it in terms of the wafer and package.

WE ALSO SORT BATCHES BY TEMPERATURE.

In order to conduct these tests in the best conditions, we have 3 test rooms including 1 ISO7 clean room across an area of more than 2000m² and organised into different areas of expertise:

- Analogue & mixed

- Digital

- Power

- RF/Microwave

- Supply chain

- Passive

- Spice modelling

Characterisation

With a presence in all sectors of activity, SERMA Technologies receives multisectoral feedback, making it an expert in electronic and environmental characterisation.

It is also equipped with numerous test platforms: Verigy 93K, Mu-Test, PXI National Instruments, Teradyne, Agilent, Rohde & Schwarz, etc.

Our expertise:

- Development of hardware and software test solutions

- Parametric characterisation in terms of T°, tension, humidity, radiation, etc.

- Evaluation of deviations following stringent environmental testing: pressure, humidity, T°, etc.

Screening

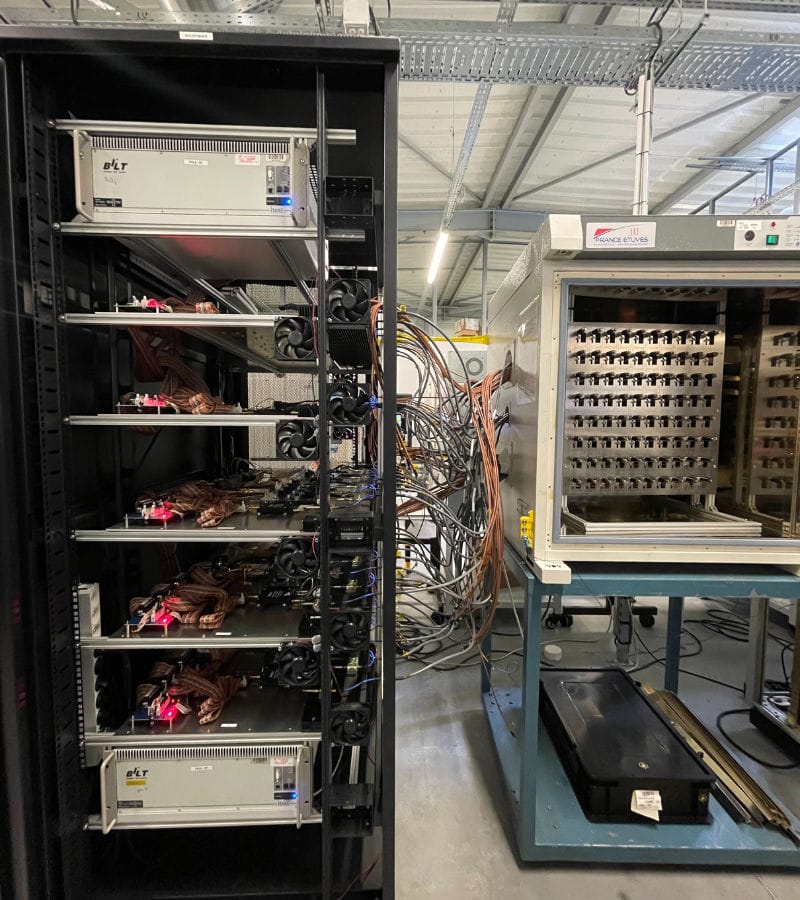

SERMA Technologies ensures the reliability of components for sectors with stringent requirements (space, defence, aeronautics) and has expert knowledge of the applicable standards: MIL- STD, SMD, ESA/ESCC, AECQ.

In addition to a number of test platforms, SERMA Technologies conducts component burn-ins with more than 60 climatic chambers and has two 8” Prober with hot chuck.

Up-Screening

SERMA Technologies sorts component batches, 100% electrically tested in an extended temperature range.

We offer a comprehensive supply chain service with component supply and also conduct input inspection tests, Go / No Go and Read & Record.

Qualification

SERMA will assist you with qualifying your components in accordance with standards or customer specifications.

With 25 years of multisectoral experience, our Experts have excellent knowledge of AECQ, MIL, ESA ESCC/ECSS, Jedec, IPC standards, etc.

We also perform qualifications in extreme climatic conditions on specific request by the customer (more than 60 climatic chambers in a dedicated building).

Our equipment includes:

- Dry ovens

- Air-to-air and liquid-to-liquid thermal shock chambers

- T°/humidity thermal cycle chambers

- HAST

- T°/humidity chambers

- Etc.

We develop specific means in order to stimulate and monitor the components during qualification.

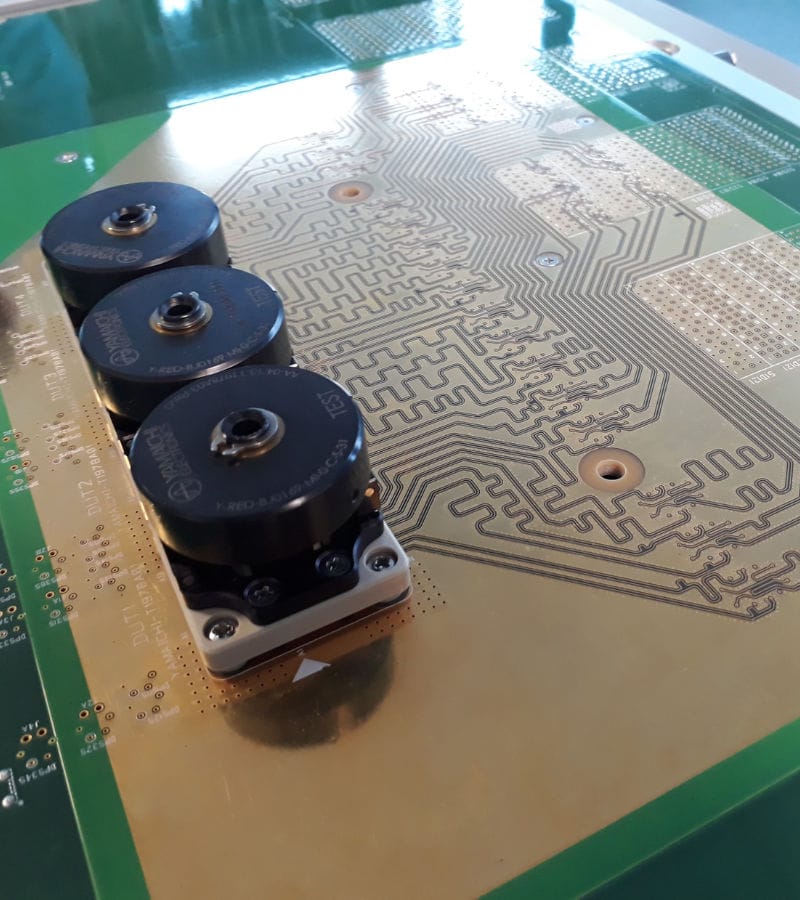

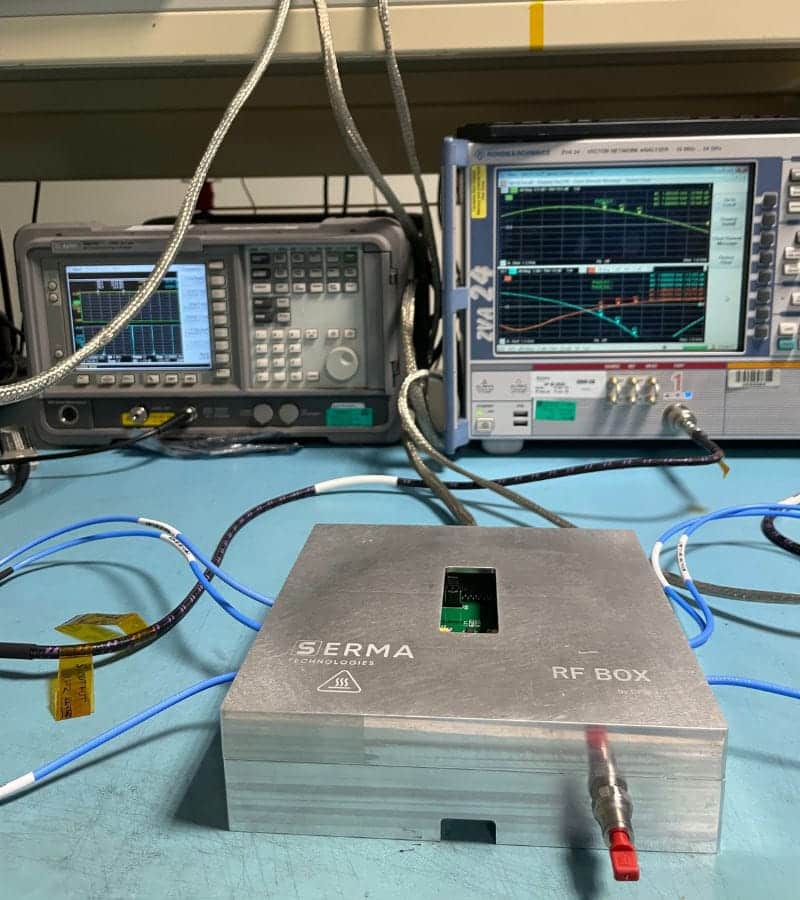

Radio frequency and microwave frequency

SERMA assesses, qualifies and ensures the reliability of RF components.

Our Experts develop and integrate product-specific test benches and test circuit boards (RO4350, RT6002 PCB).

The technical characteristics of our testing equipment and our microwave circuit boards comply with test requirements up to 24GHz.

Discover more

Measurements taken:

- S-parameters

- Noise figure

- In-band Spurious emissions

- IP3

Core equipment (Keysight Technology, Rohde & Schwarz):

- Network analyser

- Spectrum analyser

- Power meter

- Synthesiser

Types of products tested:

- Amplifier technological building blocks (LNA, HPA)

- Switches

- Frequency multiplier

- Mixers