Component management

We perform complete risk assessments, and manage your equipment obsolescence in order to improve the flow of your logistics chain.

Many electronic systems have a longer and higher quality service life than that of the components. Various industrial sectors are affected by problems with component quality assurance and obsolescence.

Compliance with regulations relating to the environment (RoHS and REACH) and export licensing (EAR, ITAR, etc.) are other constraints throughout the product life cycle.

SERMA Experts will support you in managing the availability and cost of your equipment:

- ANTICIPATE: how to develop in order to minimise the costs of equipment upgrades

- PREVENT: how to prepare for resolving problems with obsolescence to optimise the effectiveness of solutions

- REMEDY: how to identify obsolescence and handle it over time

Discover our services

- Document analysis of component reliability (PPAP)

- Complete assessment of obsolescence risks for components list: periodic alerts

- Looking for solutions in order to ensure service continuity

- Second source qualification

- Cloning

- Long-term storage advice

- Secure batch procurement and counterfeit checking

Reliability

We conduct reliability risk analyses for all types of electronic systems and suggest improvement plans as well as implementing those plans.

Our experts work on understanding the mission profile, choosing technologies and assessing COTS using reliability and robustness analyses. We strive to control costs during design.

The process enables comparative analyses to be performed on any product purchased with a non-existent or incomplete technological and technical database. We deploy a qualitative assessment method developed for your own products, and COTS, etc., based on SERMA Technologies’ experience in component, circuit board and electronic system reliability.

Discover our services

- Design review: FMECA, plan review, etc.

- Risk analysis: technologies versus mission profile

- Creation and implementation of specific reliability and robustness plans including HALT

- Creation of burn-in plans (burn-in effectiveness, burn-in safety)

- Qualification of COTS products (Components Off-The-Shelf)

- Reliability audit

- Operational maintenance study, Health monitoring

- Physical laboratory analysis of circuit boards and systems focused on:

- Electrical protection

- Identification of critical components

- Technological choice

- Component assembly

- Industrialisation of circuit boards

- Chemical protection

- Quality of assembly

- Product robustness

Root cause analysis and support with problem-solving

Whether on a component, circuit board or electronic system level, we offer all of our technological expertise as well as rigorous analysis methods in order to identify the root causes of recurring malfunctions, random failures and availability problems. We will then help you to implement remedial actions and assess their effects.

Stages of an analysis

- Context analysis

- Pre-analysis of risks or factors of failure occurrence

- Brainstorming and debrief, 8D, DOE, etc.

- Description of failure mechanisms and investigation plan

- Physical and electrical analysis

- Fault reproduction

- Use of results

- Proposal, implementation and monitoring of remedial actions

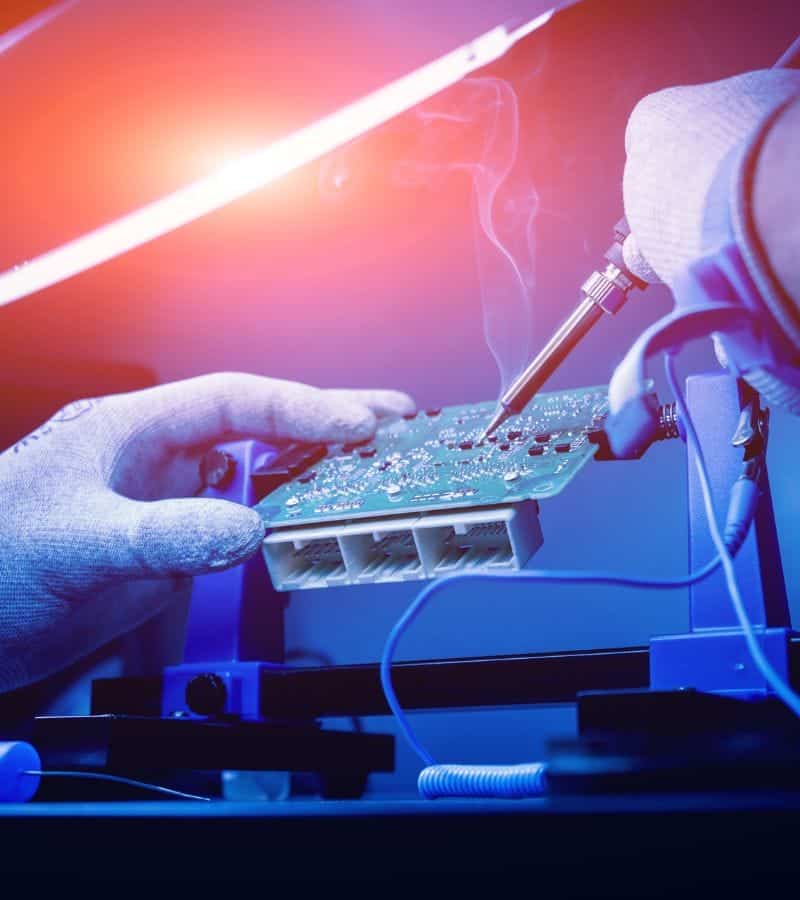

Assembly processes

Physical analysis of circuit boards in the laboratory, combined with our assembly line auditing skills, enable us to help you improve manufacturing processes and eliminate variability.

We conduct audits on components, circuit boards, batteries, and wiring harnesses worldwide, and we offer you our experience in various sectors such as aeronautics, space, automotive, rail, and general public, etc.

Discover our services

- Solving assembly problems for all technology types

- Qualification of new processes or new products

- Selecting new suppliers

- Analysing feasibility and managing the transfer of industrial production from one site to another

- Conducting PFMEA, monitoring process plan flows

- Complete project management for industrialisation of electronics (change of production site, site search)

Industrialisation

We will manage your industrial project to introduce new products or transfer manufacturing between different sites. Our experts will analyse the technical feasibility, the related costs, and the impacts in order to provide you with the necessary decision-making tools.

Your objectives are analysed by our experts

The industrial context:

- Introduction of new products

- Industrial transfer

- Deindustrialisation / Reorganisation

- Supplier selection

- Capacity optimisation

Associated needs:

- Schedule

- Project management

- Manufacturing costs

- Transfer strategy study

- Transfer costs

- Training

Reinforced or driven by:

- Technical developments

- New ranges

- Acquisitions

- Quality issues

- Withdrawal

- Cost reduction

- Changes in demand

- Product complexity

- Diversity of stakeholders

- Unavailable skills or resources

- Time constraints

Maintainability

SERMA Technologies will support you with the maintainability of your equipment envisaged from the design phase up to operational maintenance.

Health Monitoring

Health Monitoring will enable you to optimise the lifespan of your products whilst reducing maintenance costs.

Maintaining an installed base in operational condition whilst ensuring operational savings is essential for operators.

Through Health Monitoring, SERMA will support you and help you to anticipate as much as possible the risks of failure of your systems.

The aim is to reduce maintenance operations to a strict minimum and to limit breakdowns.

We have monitoring tools that help with:

- Reducing maintenance costs

- Improving operating costs

- The maximum availability of your installed base

Prognostics and Health Management

Contenu à définir