SERMA Technologies monitors the manufacturing processes for components and circuit boards as well as materials (brazing) used through circuit board verification programmes: PCBA and PCB.

Qualification

Bare PCB

In order to prevent future problems with via cracking, delamination, CAF or in the event of a change of supplier, we will support you in the qualification of your rigid and flex PCBs with our dedicated expert resources.

We will conduct a series of analyses enabling us to assess the quality of a bare or assembled printed circuit board in relation to standards or according to the customer’s specifications.

We have expert knowledge of the IPC, MIL, IEC, ECSS, and JDEC standards and conduct various types of analysis.

Know more

- Finishing thickness measurement: AuNi, SnPb, Sn, Ag, using X-ray fluorescence

- Dimensional measurements

- Bow and twist

- Wetting analysis

- Ionic contamination measurement

- Microsectioning

- Solder float test

- Tg glass transition measurement

- Time to delamination measurement

- Etc.

PCBA

In order to monitor the quality of your products, we examine the condition of the brazing of various alloys and their behaviour over time through ageing tests. These studies are conducted in relation to standards (IPC, ECSS, etc.) and with respect to the state of the art.

Non-destructive methods

- Binocular observation (wetting, residue, etc.)

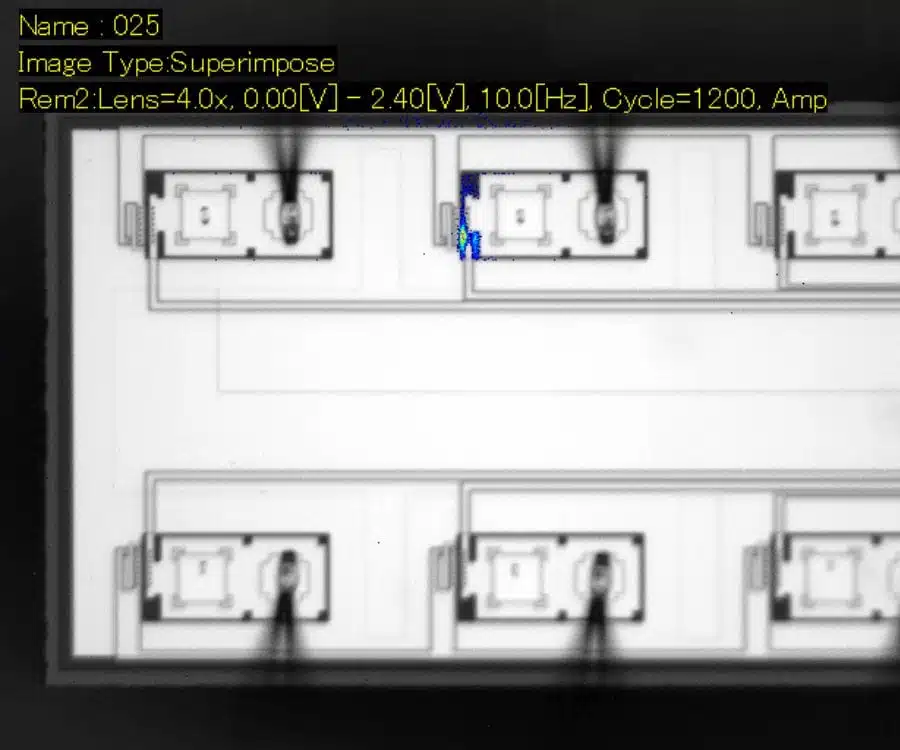

- X-ray analysis (bubbles in joints, wicking in plated-through holes)

- Acoustic microscopy on thin package plastic components

Destructive methods

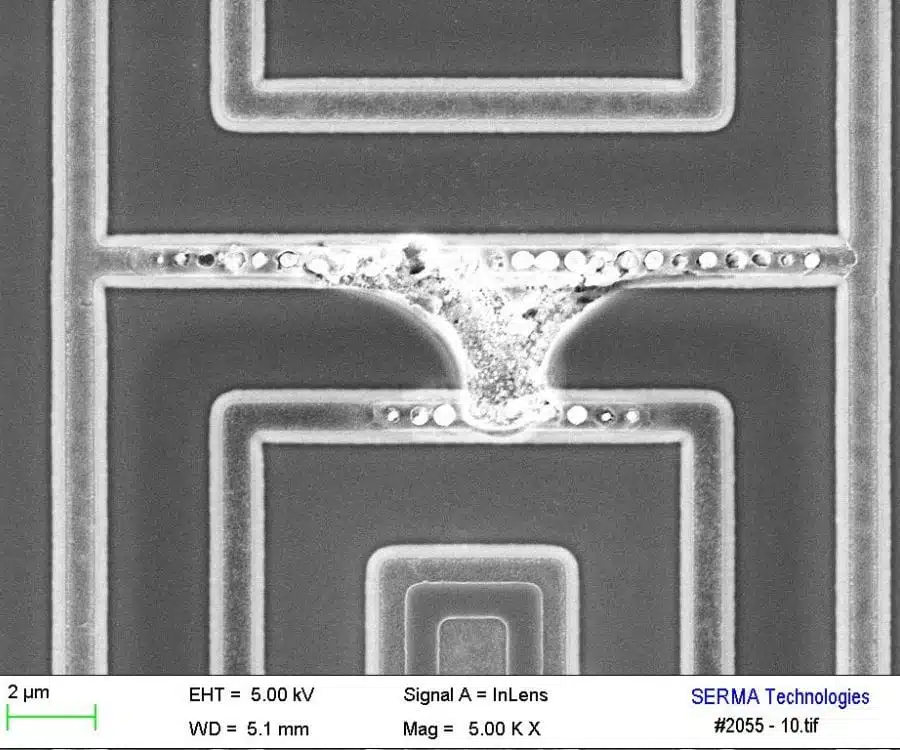

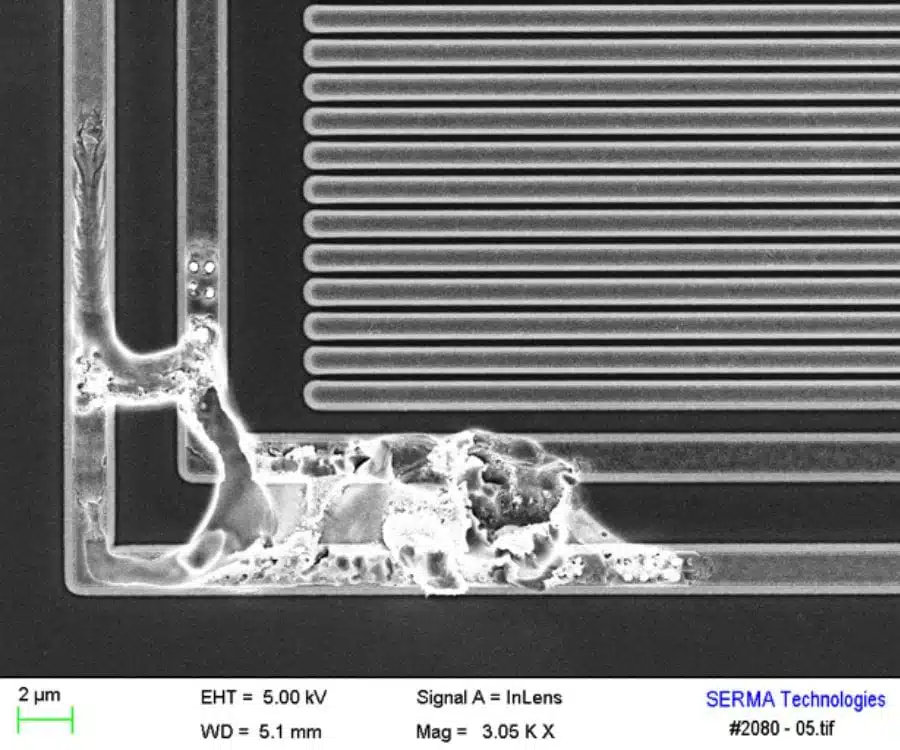

Through microsectioning, and optical and SEM inspections, we conduct the following analyses:

- Study and measurement of intermetallic thicknesses: excessive brazing, lead, lead-free (RoHS)

- Verification of the brazing structure

- Detection of impurities

- Study of fatigue, cracking

The report provided is a factual review of the condition of the product and non-compliances. As part of a critical process report, it will be accompanied by recommendations in order of criticality.

Analysis and failure

We carry out destructive and non-destructive analyses in order to expose failures such as:

- PCB contamination and corrosion

- Electromigration (CAF) and delamination

- Finish defect (Black pad effect)

- Electrical contact problem

- Whiskers

- Brazing failure