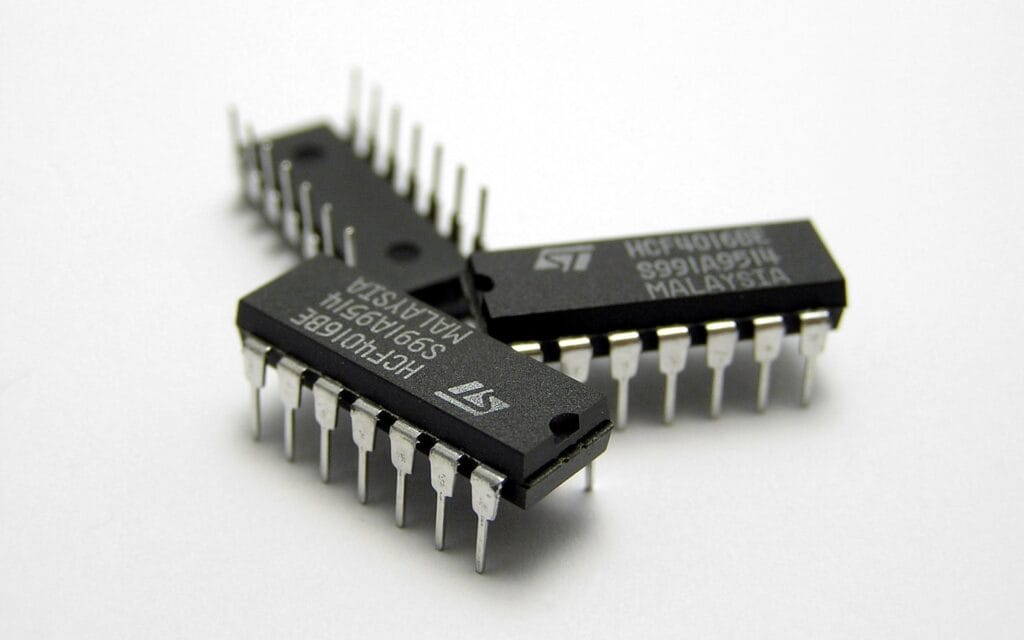

The supply of obsolete components (and often from batches of unknown origin), has led SERMA Technologies to implement specific testing procedures in accordance with international standards, enabling their authenticity and quality to be guaranteed.

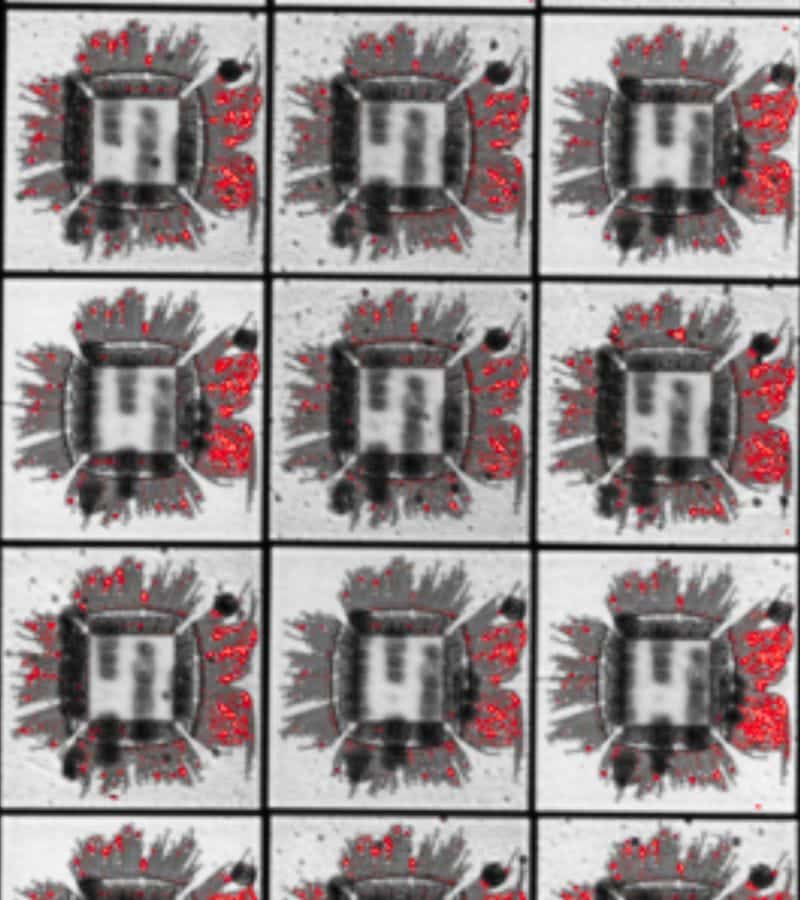

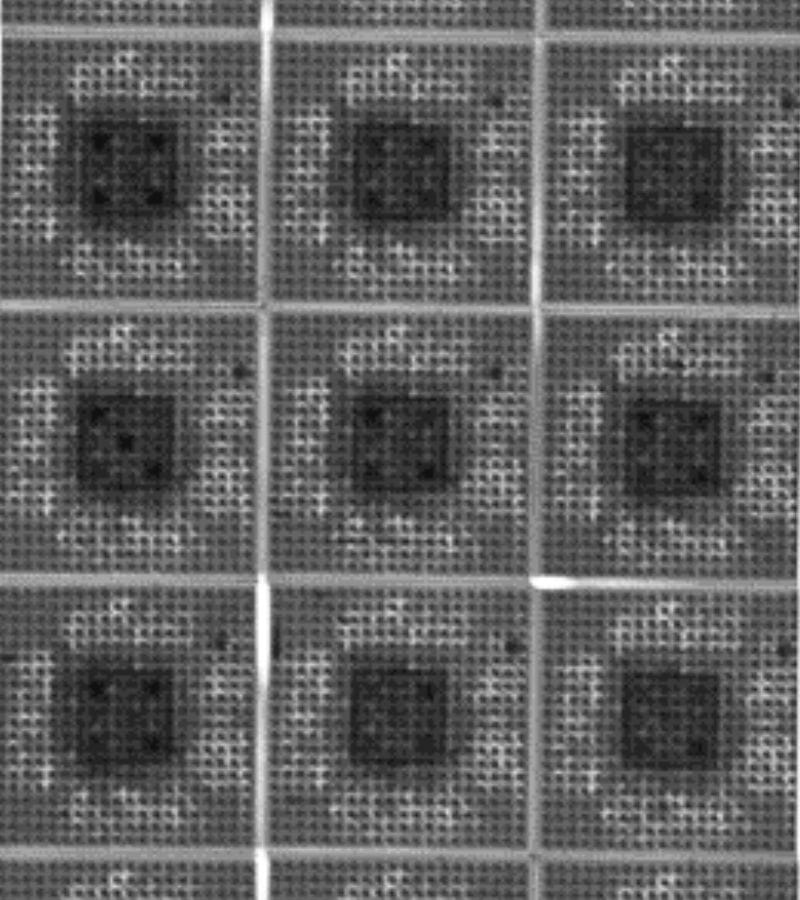

The aim is to eliminate any defective components and to check whether batches are forged or counterfeited. We check whether the batches contain physically defective parts due to an incorrect manufacturing process (weak internal connections, corrosion, voids in chip attachment, etc.) or on account of incorrect storage conditions (oxidation of pins, plastic package delamination, damage caused by electrostatic discharges) in several ways:

- External visual examination

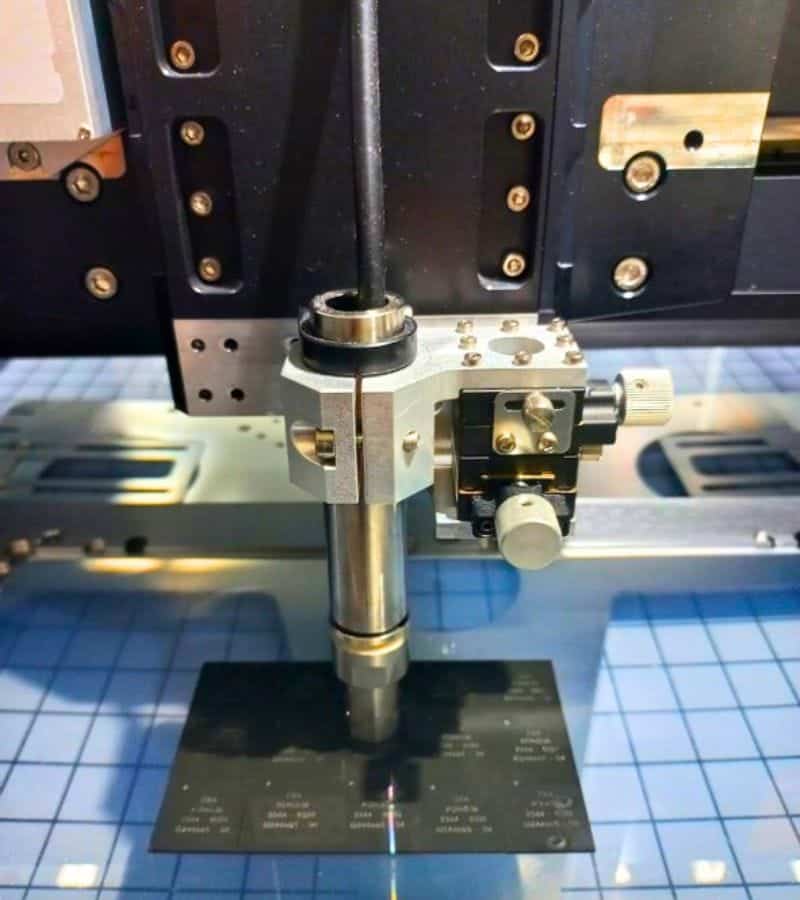

- X-ray

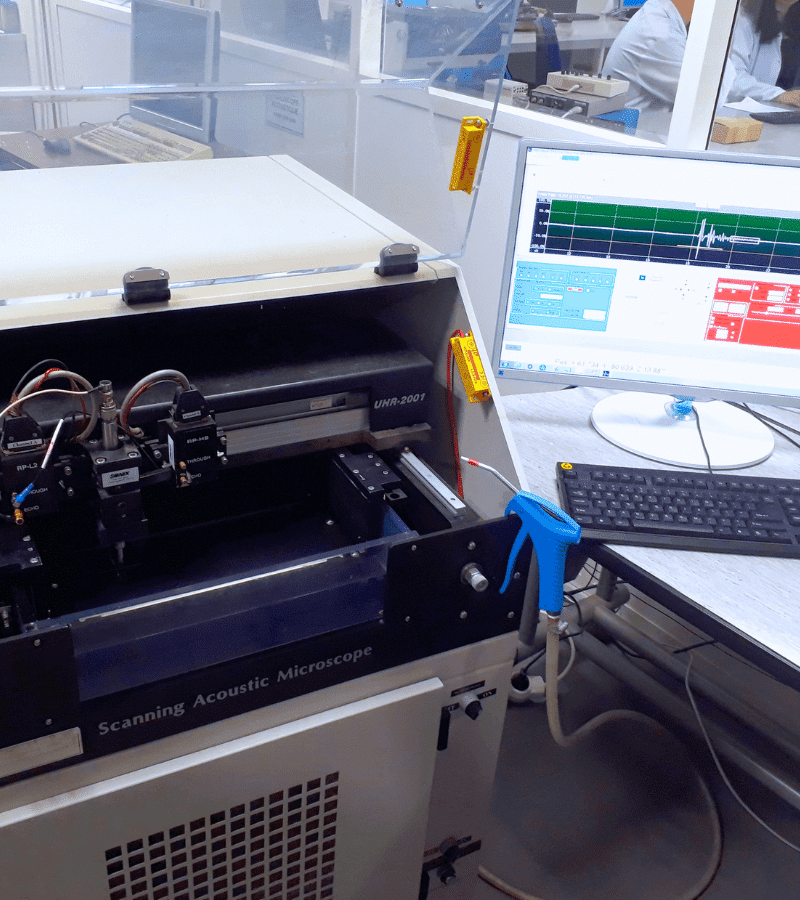

- Acoustic microscopy (plastic components)

- Parametric electrical testing I(V) at room temperature or at temperature (-55/+125°C)

- Component opening, identification of chip markings, comparison with a reference part if available or SERMA Technologies database

- Internal visual inspection, assembly and chip construction quality control

- Summary report with expert opinion regarding the acceptance or rejection of the batch

We also have specific security procedures suited to each customer’s needs:

- Wire tensile testing

- Shear testing of microsoldering

- Connection wetting testing (former code dates)

- Hermeticity testing (hermetic packages)

- Electrical testing on the main parameters adjusted to each type of component and according to the availability of testing solution in the SERMA libraries

Obsolescence management is a critical challenge for ensuring the longevity and performance of your products.

That’s why, for over 10 years, SERMA Technologies has developed its OBSOGERANCE® solution.

- Prevent obsolescence risks.

- Detect obsolescence risks.

- Solve obsolescence risks.